In today's competitive and highly regulated environment, the purity of water used in your operations is not just a line item—it's a critical factor in product quality, equipment longevity, and regulatory compliance. Businesses constantly face the challenge of removing a complex array of contaminants, from simple chlorine to emerging compounds like PFAS. The solution is often found in a surprisingly simple yet powerful technology: Granular Activated Carbon (GAC).

This comprehensive guide is written for business leaders and managers who need a clear understanding of GAC. We will explore what it is, how it works, what it removes, and how to select the right system to protect your operations and bottom line.

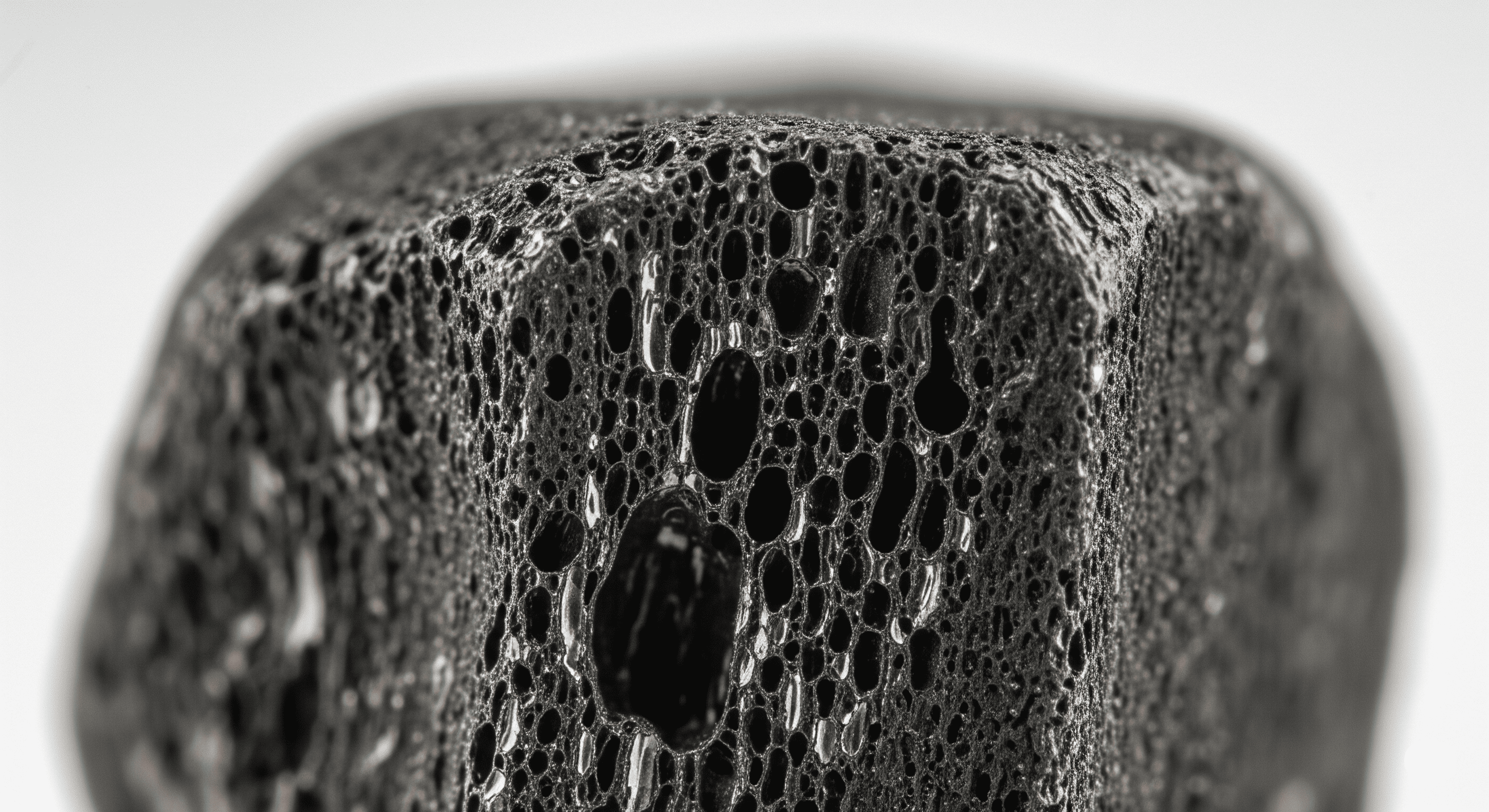

At its core, Granular Activated Carbon is a specially processed carbon material with a crucial characteristic: an incredibly porous internal structure. Think of a single granule of GAC as a tiny, rigid sponge filled with microscopic tunnels and pores. This structure gives it an enormous internal surface area—a single gram of GAC can have the surface area of a football field.

This high surface area is the key to its effectiveness in water treatment. GAC is typically produced from carbon-rich raw materials like coconut shells, bituminous coal, or wood. The choice of material impacts the carbon's final properties, influencing its hardness and the size distribution of its pores, which determines its effectiveness against specific contaminants.

While both are effective, GAC and PAC are used in different applications. The primary distinction is particle size, which dictates how they are used in a treatment system.

| Feature | Granular Activated Carbon (GAC) | Powdered Activated Carbon (PAC) |

|---|---|---|

| Particle Size | Larger, sand-like granules (0.2 to 5 mm) | Fine powder (< 0.18 mm) |

| Application | Used in filter beds (vessels/columns) for continuous flow. | Dosed directly into water, then removed later. |

| Use Case | Ideal for long-term, continuous filtration systems. | Best for seasonal or short-term contaminant spikes. |

| Reusability | Can be reactivated and reused multiple times. | Generally single-use. |

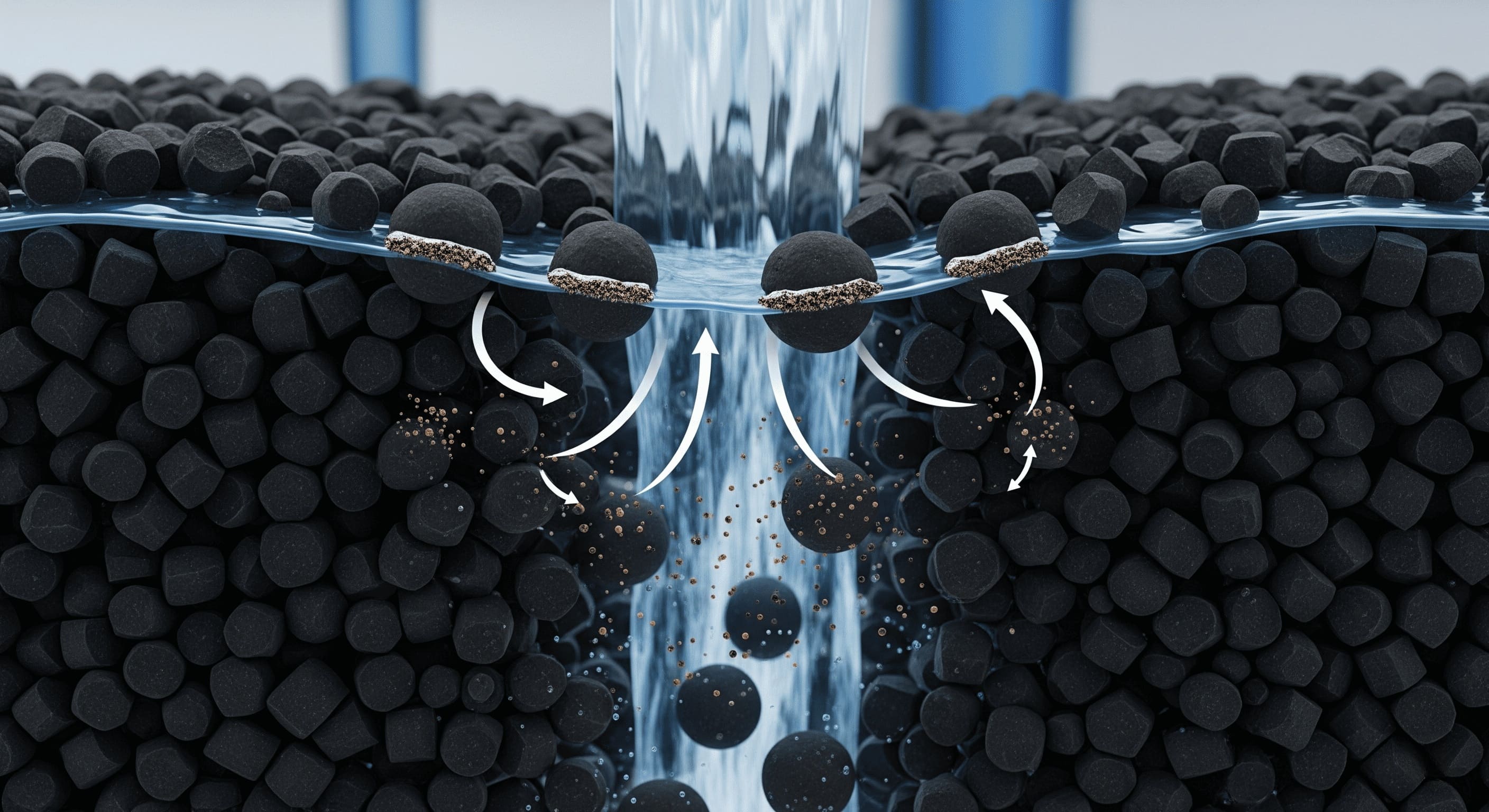

Granular activated carbon purifies water through a physical process called adsorption. It's important not to confuse this with absorption. While absorption is like a sponge soaking up water, adsorption is a surface phenomenon where contaminants stick to the outside of a material.

Imagine GAC's vast internal surface as a massive magnet for specific organic impurities. As contaminated water flows through a bed of GAC, the unwanted molecules are pulled out of the water and held firmly onto the carbon's surface, allowing pure water to pass through.

The effectiveness of the activated carbon adsorption process is not absolute. It depends on several key operational factors:

A GAC filter is one of the most versatile tools in water treatment, effective against a wide range of substances that affect water safety and quality.

| Contaminant Category | Specific Examples |

|---|---|

| Disinfection & Byproducts | Chlorine, Chloramine (reduces bad taste and odor) |

| Volatile Organic Compounds (VOCs) | Benzene, Toluene, Xylene, TCE, PCE |

| Taste and Odor Compounds | Geosmin, MIB (earthy or musty tastes/smells) |

| Pesticides & Herbicides | Atrazine, Simazine |

| Emerging Contaminants | Per- and Polyfluoroalkyl Substances (PFAS), Pharmaceuticals |

Based on documented performance, the removal efficiency of high-quality GAC is impressive. Specific capabilities include:

Moving from the media to the machinery, a GAC water filter system is the practical application of this technology. For commercial and industrial use, these systems typically involve one or more large vessels containing beds of GAC media. The design and sizing of the system are critical for performance and cost-efficiency.

Ask these questions to ensure you invest in the right solution:

Client: A mid-sized Chemical plant facing stringent environmental discharge regulations.

Challenge: The client's wastewater contained high concentrations of Volatile Organic Compounds (TCE and Benzene), exceeding municipal limits and posing a risk of fines and operational shutdowns.

Solution: Our engineering team analyzed their wastewater profile and flow rates. We designed and implemented a dual-vessel GAC system using our high-performance Granular activated carbon GAC, specifically selected for its high adsorption capacity for VOCs.

Results: Within the first month of operation, the system achieved a 99.8% reduction in target VOCs, bringing their wastewater into full compliance. The client avoided regulatory penalties and established a more sustainable and predictable water management process.

Your GAC media will not last forever. Over time, its surface area becomes saturated with contaminants, and its performance declines—a state known as "media exhaustion." At this point, the media must be either replaced or reactivated.

Thermal reactivation is a process where spent GAC is heated in a controlled furnace to over 800°C. This process vaporizes and destroys the adsorbed contaminants, restoring the carbon's porous structure and adsorptive capacity. Reactivation is a cost-effective and environmentally sustainable choice for many businesses.

Choosing the right GAC is only half the battle. True success comes from proper system design, media selection, and ongoing technical support. A knowledgeable partner ensures your system is optimized for performance and delivers the lowest total cost of ownership.

Here’s what sets us apart:

Call to Action: Ready to design a GAC solution that meets your specific needs? Contact our engineering team for a free consultation today.

What is the typical lifespan of GAC in a water filter?

The lifespan depends heavily on the water quality and usage rate, ranging from a few months to several years. Regular testing is key to determining the replacement schedule.

Is GAC effective at removing heavy metals like lead?

Standard GAC is not effective for removing heavy metals like lead or arsenic. However, specialized catalytic or impregnated carbons can be used for this purpose.

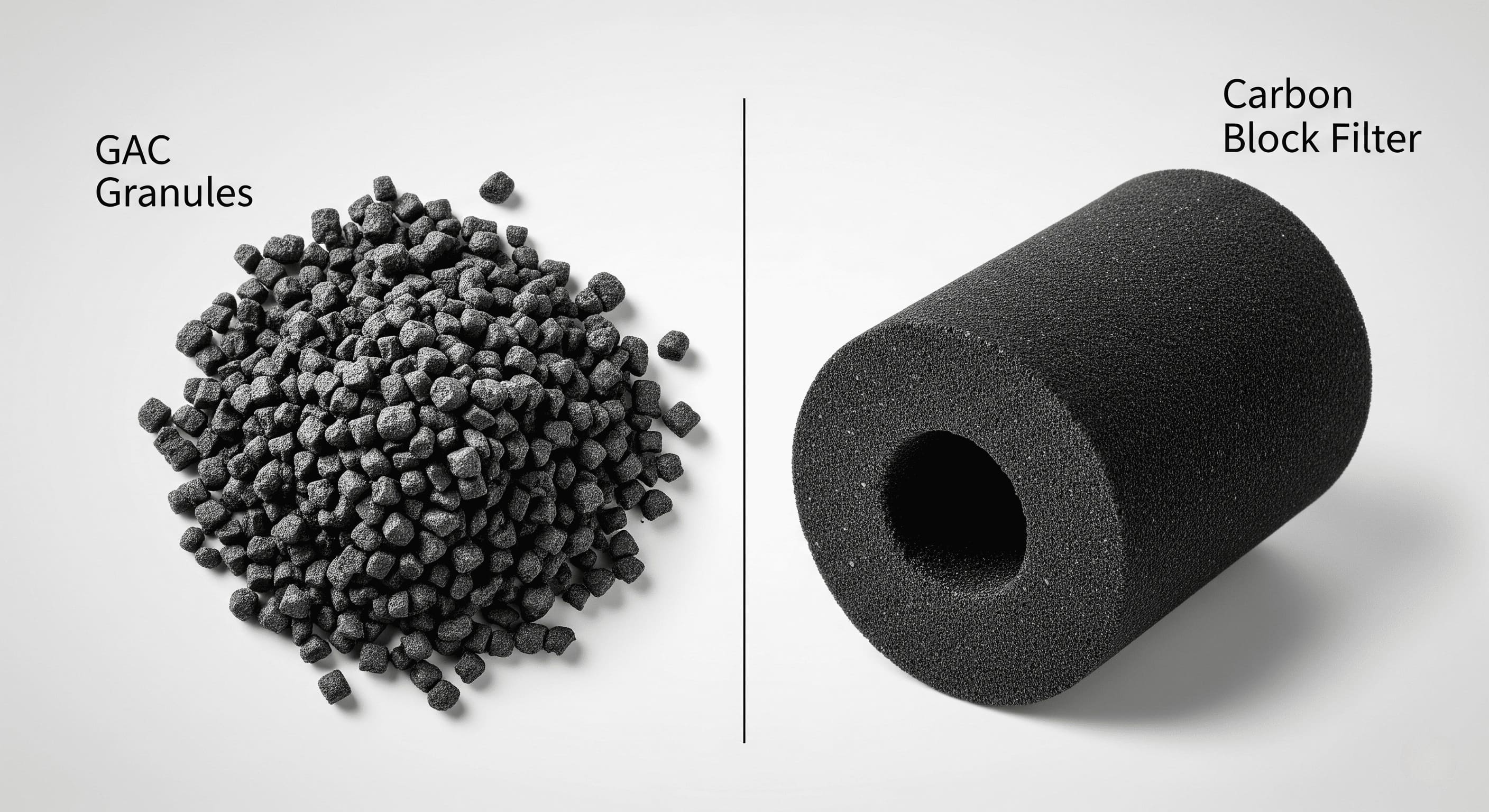

What is the difference between GAC and carbon block filters?

GAC filters use loose carbon granules, while carbon block filters are powdered carbon compressed into a solid block. Block filters often have a smaller pore size and can provide a higher degree of fine sediment removal.

Are there any contaminants that GAC cannot remove?

Yes. GAC is generally ineffective against dissolved inorganic compounds like nitrates, fluoride, and most minerals.

JyenLoo is a Senior Water Treatment Specialist at Yongruida Carbon Co., Ltd. with over 15 years of experience designing and implementing industrial water purification solutions. He specializes in activated carbon technologies and is dedicated to helping businesses achieve their water quality and sustainability goals.

Ningxia Yongruida Carbon Co,.Ltd was founded in

2003.With an area of over 50000 square meters ,our

factory is located in the city of Shizuishan Ningxia .