Ensuring purity and eliminating contaminants are critical in any industrial process. For businesses seeking a reliable, cost-effective, and sustainable solution, the answer may lie in a unique, high-performance material: coconut shell activated carbon. While various forms of activated carbon exist, the version derived from coconut shells offers distinct purity, strength, and efficiency advantages, making it the superior choice for many commercial applications.

This guide is written for B2B buyers, engineers, and procurement managers. We will provide a comprehensive overview of coconut shell activated carbon, detailing its production, clear advantages over alternatives, and the most effective industrial uses. Our goal is to equip you with the knowledge to make an informed purchasing decision that enhances your operational performance and ROI.

The journey from a tropical coconut to a high-tech purification medium is a marvel of material science. The process begins with sourcing high-quality coconut shells from key regions like Vietnam, Indonesia, and the Philippines. These raw materials are transformed through a meticulous, multi-step process to create a vast internal network of microscopic pores.

The production involves two primary stages:

Our process utilizes a proprietary rotary high-temperature furnace, ensuring uniform heat distribution. This advanced technology results in a highly consistent pore structure from batch to batch, guaranteeing predictable and reliable performance for our clients.

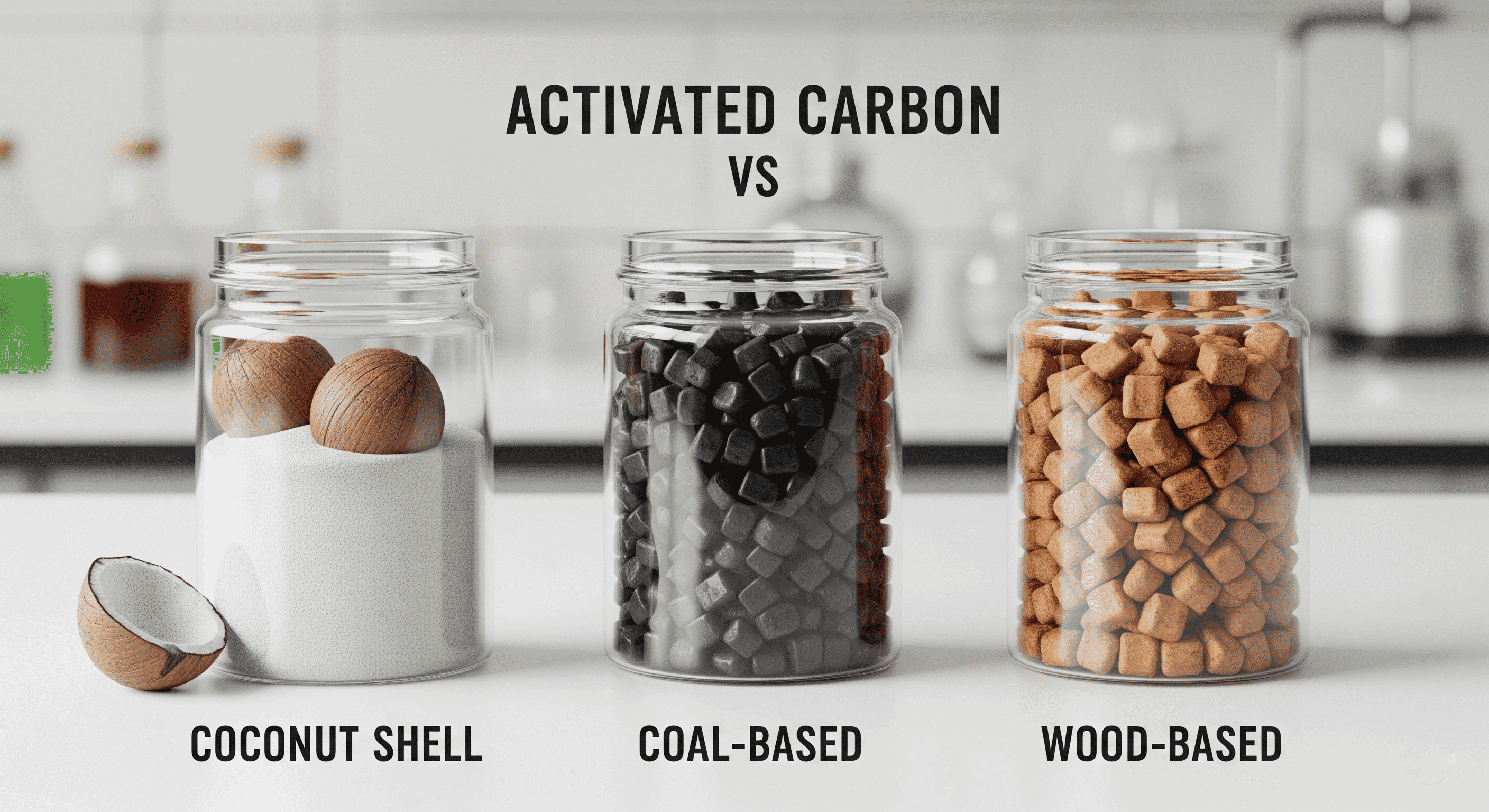

Not all activated carbon is created equal. For a commercial buyer, choosing coconut, coal, or wood-based carbon significantly affects performance, product longevity, and operational costs. Coconut shell-based carbon consistently outperforms its counterparts in the areas that matter most for industrial applications.

Here is a direct comparison:

| Feature | Coconut Shell Activated Carbon | Coal-Based Activated Carbon | Wood-Based Activated Carbon |

|---|---|---|---|

| Primary Pore Structure | High Microporosity (<2 nm) | Mesopores & Macropores | High Macroporosity (>50 nm) |

| Best For | Removing fine impurities, trace organic contaminants, and ensuring high purity (e.g., drinking water, chemical purification). | General purpose, suitable for color and larger molecule removal. | Gas-phase applications, decolorization of liquids. |

| Hardness / Durability | Extremely High (>98%) | High | Low / Brittle |

| Product Loss | Minimal; withstands high pressure and regeneration cycles. | Moderate; can be prone to fracturing. | High; not suitable for abrasive environments. |

| Ash Content (Purity) | Very Low (<3%) | Moderate (can be high) | Low |

| Environmental Impact | Sustainable; made from a renewable resource (waste coconut shells). | Non-renewable fossil fuel source. | Renewable, but contributes to deforestation if not sustainably sourced. |

The technical specifications translate directly into tangible business advantages. Companies choose coconut shell activated carbon to improve product quality, reduce operational costs, and meet stringent regulatory standards.

The defining feature of coconut shell carbon is its high concentration of micropores. This gives it a massive specific surface area—between 1100 and 1300 m²/g—providing a larger active field for adsorption. This structure is exceptionally effective at trapping small organic molecules and trace contaminants. It is the ideal choice for applications demanding the highest purity levels.

In industrial settings, activated carbon must withstand demanding conditions. Our product boasts a Ball-Pan Hardness grade of over 98%. Unlike fragile coal-based carbons, this minimizes product degradation and dust generation during handling, backwashing, and regeneration. The result is a longer service life, less frequent replacement, and lower overall operational costs.

Ash is an inert, inorganic material within activated carbon with no adsorptive capacity. A high ash content can leach into and contaminate the final product. Our coconut shell activated carbon features a very low ash content of less than 3%, ensuring it does not compromise the purity of the treated liquids or gases.

Sustainability is no longer a talking point; it’s a core business metric. Coconut shell activated carbon is produced from the discarded shells of coconuts, a renewable and readily available resource. This provides a greener footprint than coal-based alternatives, helping companies achieve their environmental and corporate social responsibility goals.

The unique properties of coconut shell activated carbon make it indispensable across various industries.

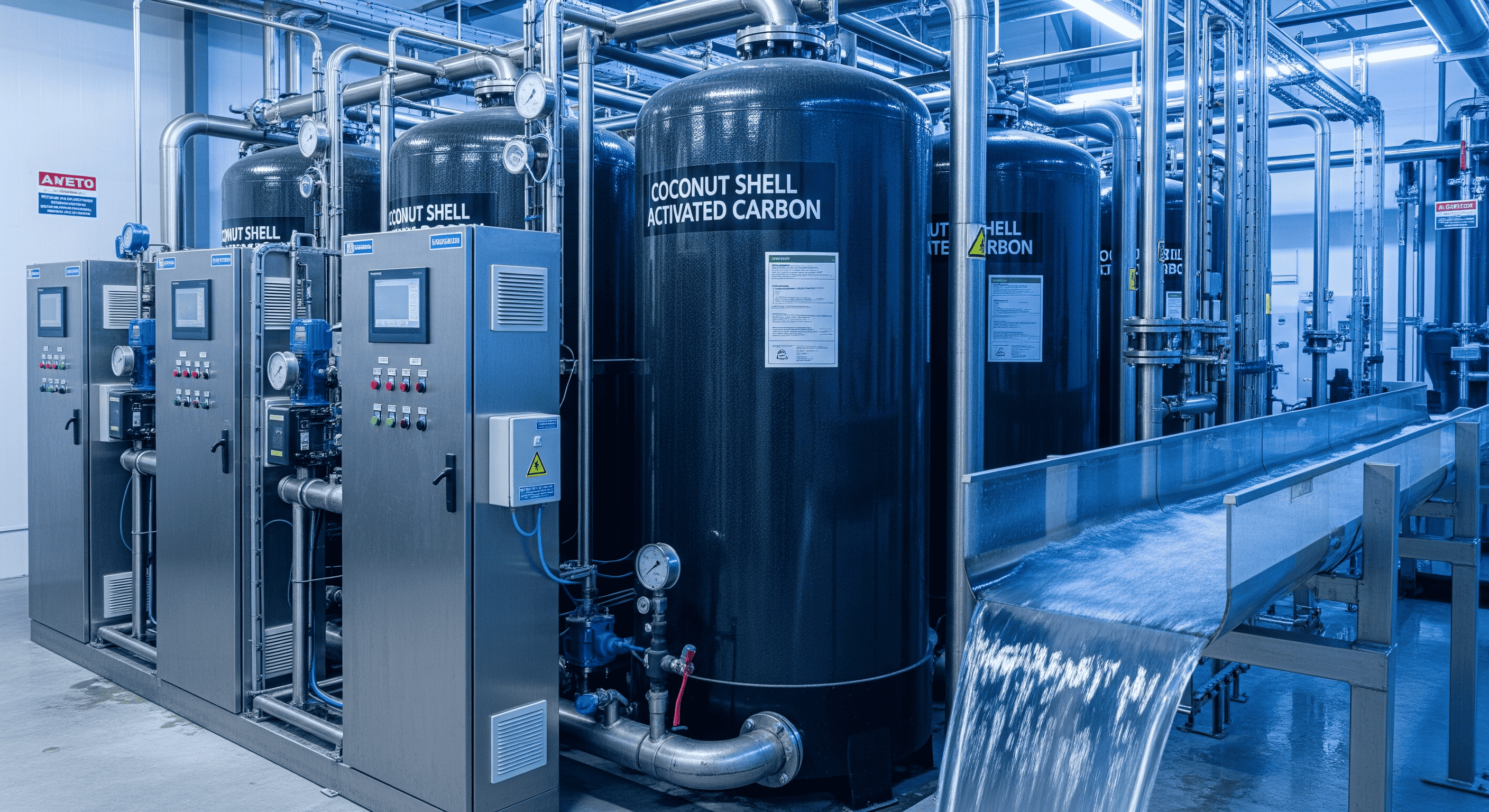

This is the most extensive application, spanning municipal drinking water to industrial process water. Its effectiveness at removing disinfection byproducts (THMs), volatile organic compounds (VOCs), pesticides, and trace contaminants makes it essential for meeting strict regulatory standards. It is the primary material used in high-quality coconut shell activated carbon filters for point-of-use and point-of-entry systems.

Purity is paramount in the food and beverage industry. Here, coconut shell activated carbon is used for decolorization, taste and odor removal, and purification.

Case Study: An Israeli manufacturer faced persistent problems with pigment impurities in their syrup. After integrating our coconut shell activated carbon into their workflow, they achieved a 95% reduction in the product’s color index. This enhancement in quality allowed them to label their product as ‘high purity’ for the first time, opening up new premium market opportunities.

Its microporous structure is highly efficient at adsorbing VOCs, hydrogen sulfide, and other odorous compounds from air streams in industrial facilities, manufacturing plants, and commercial buildings.

In high-stakes chemical and pharmaceutical production, coconut shell activated carbon is used as a catalyst support and for the purification of final products, where its high purity and low ash content are critical.

Partnering with the right supplier is as important as choosing the right material. Use this checklist to vet potential suppliers and ensure you receive a high-quality, reliable product.

Q1: What is coconut shell activated carbon primarily used for?

A: Its primary use is in purification applications where high purity is essential. This includes drinking water filtration, beverage processing, air purification, and removing fine organic contaminants from liquids and gases.

Q2: Is coconut shell carbon better than charcoal?

A: Yes, for most high-performance applications. While both are forms of carbon, coconut shell activated carbon has a higher surface area, a more microporous structure, greater hardness, and lower ash content. This makes it more efficient at removing small contaminants and more durable in industrial processes.

Q3: How long does coconut shell activated carbon last?

A: The lifespan depends entirely on the application, the concentration of contaminants, and the flow rate. A drinking water filter can last from several months to a year. Its high durability in industrial settings allows it to be regenerated and reused multiple times, significantly extending its service life.

Q4: Is activated carbon from coconut shells safe for drinking water?

A: Absolutely. It is considered one of the safest and most effective materials for drinking water purification. Look for products certified to NSF/ANSI standards to guarantee they are safe and effective for this purpose.

[Your Name/Company Name] is a leading authority in purification solutions, with over a decade of experience manufacturing and applying high-performance activated carbon. Specializing in coconut shell-based products, we empower industrial and commercial partners across Europe and the Americas to achieve superior purity, operational efficiency, and sustainability goals. Our commitment to quality is backed by rigorous data, industry-leading technical expertise, and a proven track record of solving complex purification challenges.

Ningxia Yongruida Carbon Co,.Ltd was founded in

2003.With an area of over 50000 square meters ,our

factory is located in the city of Shizuishan Ningxia .