For many plant managers, activated carbon is considered a necessary line item in the operational expenditure budget—a consumable commodity purchased based on its price per ton. This perspective, while common, overlooks a critical reality: the activated carbon you choose is not just a cost, but a powerful operational asset. The microscopic structure engineered into each granule has a direct and macroscopic impact on your plant's efficiency, reliability, and, ultimately, its profitability.

The purpose of this guide is to move beyond the simple procurement mindset and provide a clear, practical framework for evaluating activated carbon based on its total financial and operational impact. We will connect the complex technical specifications of this material to the outcomes that matter most to you—reduced downtime, lower labor costs, consistent product quality, and mitigated compliance risks. By understanding how to translate pore size to profitability, you can transform a routine purchase into a strategic decision that delivers a measurable return on investment.

At its core, activated carbon works through adsorption, where contaminant molecules in a liquid or gas stream adhere to its vast internal surface. This internal surface is a complex network of microscopic pores, and the size and distribution of these pores determine what the carbon can effectively capture.

Think of a granule of activated carbon as a microscopic sponge, but one with a highly specialized structure. Its effectiveness comes not just from having many holes, but from having the right size of holes for the specific job. The challenge is to match the pore structure of your "sponge" to the molecular size of the impurities you need to remove.

(1).jpg)

The internal pore network of activated carbon is generally classified into three categories. A high-performance carbon does not have the most pores, but one that has the optimal distribution of pore sizes for a specific application.

The raw material used to produce the activated carbon is a primary factor in determining this final pore structure.

| Pore Type | Relative Size | Best For Capturing... | Common Raw Material Source |

|---|---|---|---|

| Micropores | Smallest | Small molecules, trace contaminants, VOCs | Coconut Shell |

| Mesopores | Medium | Larger organic molecules, color bodies, dyes | Wood |

| Macropores | Largest | Transport pathways, giant molecules | Wood, Coal |

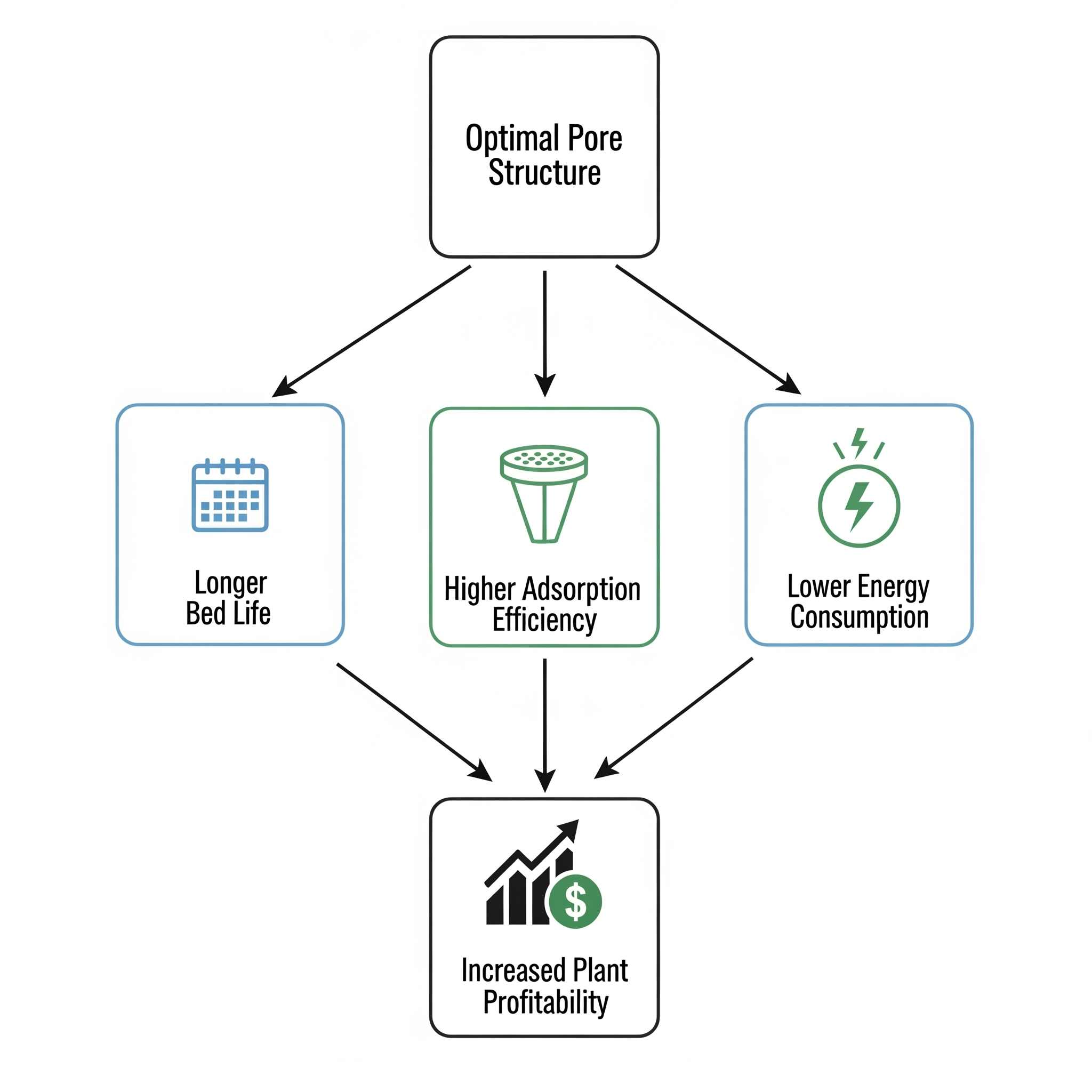

Understanding the science of pore structure is the first step. The next, more critical step for a plant manager is connecting that science to the key performance indicators (KPIs) that drive your operation: cost, efficiency, and risk.

Selecting a carbon with the optimal pore structure for your target contaminants maximizes its working capacity. This directly translates to a longer service life, or "bed life." A longer bed life means fewer changeouts, which generates a cascade of savings:

Conversely, using a general-purpose carbon poorly matched to your application can lead to inadequate bed life, forcing more frequent and costly changeouts.

When the pore distribution is correctly matched to the contaminants, the entire carbon bed works efficiently, preventing a situation known as premature breakthrough, where contaminants pass through the filter before the media is fully saturated. Key quality metrics like the Iodine Number are a valuable proxy for a carbon's total micropore volume and its potential performance and value in removing small contaminants. A higher-performing carbon means more purification from every pound, optimizing your media consumption.

The activated carbon's physical form and particle size influence the pressure drop across the filter bed. A higher pressure drop means your pumps and blowers must work harder, consuming more energy. While Granular Activated Carbon (GAC) is designed to offer low-pressure drops, other forms like Extruded Activated Carbon (EAC), or pellets, are engineered explicitly for gas-phase applications to provide excellent flow dynamics with minimal pressure drop, directly impacting your plant's energy bill.

Finally, the choice of activated carbon must be framed in terms of risk mitigation. The consequences of a purification system failure—whether it results in a failed product batch, a costly recall, or a significant environmental compliance fine—will almost always dwarf the initial cost of the carbon media itself. Investing in a high-performance, correctly specified activated carbon is a critical insurance policy against these high-cost events.

The optimal pore structure doesn't happen by accident. It directly results from two critical factors: the raw material source and the manufacturing process used to create the activated carbon. Understanding these factors will help you ask more intelligent questions of potential suppliers.

Different carbonaceous raw materials have inherent physical properties that make them better suited for specific applications.

The raw material is first carbonized by heating it in an oxygen-free environment. Then it undergoes "activation" to develop its porous structure.8 The two primary methods are:

A sophisticated manufacturing process, such as a "5th generation double steam activation process," is a key indicator of a high-performance product that will deliver superior consistency and longer bed life compared to a less advanced, general-purpose carbon.

With this knowledge, you can move from being a price-taker to an informed buyer. Use this checklist to evaluate your current or potential activated carbon supply and ensure you make the most profitable decision for your plant.

Based on a clear understanding of how technical specifications drive business outcomes, a strategically activated carbon choice is a powerful tool for improving plant profitability and mitigating operational risk. By looking beyond the initial price per ton and focusing on performance, bed life, and total cost of ownership, you can ensure your purification system is not a cost center, but a source of strategic advantage.

Ningxia Yongruida Carbon Co,.Ltd was founded in

2003.With an area of over 50000 square meters ,our

factory is located in the city of Shizuishan Ningxia .