This article explains how activated carbon works, where it is used, what makes it high-quality, and the potential problems that may arise.

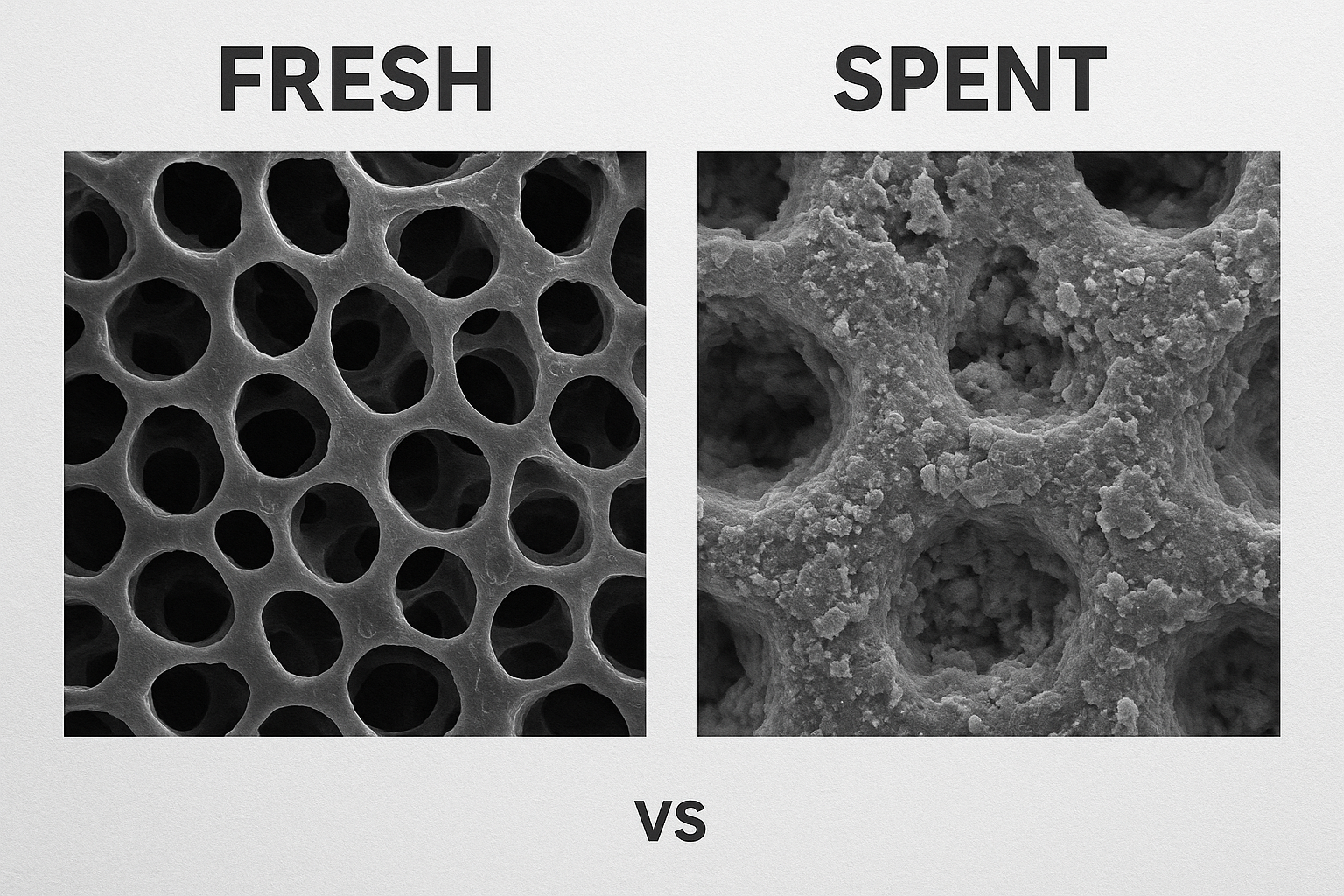

Activated carbon is a special form of carbon. It has many tiny holes inside, which give it a large surface area (500–3,000 m² per gram). These holes let it catch and hold gases, chemicals, and liquids on its surface.

There are two main steps:

This creates a strong, porous material that is ready to adsorb (not absorb) many substances.

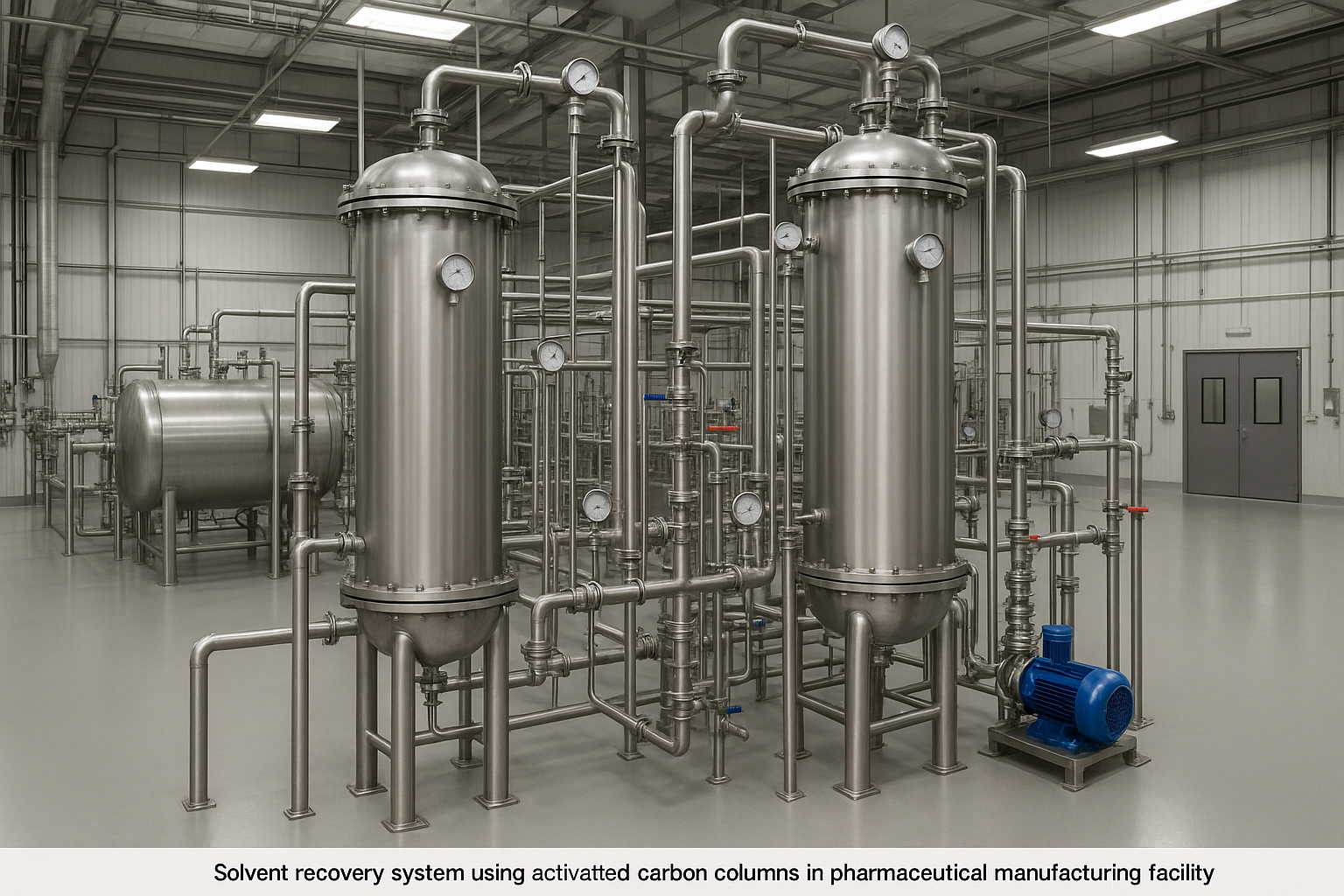

Factories, such as those producing paint, drugs, and printing materials, use carbon to capture harmful vapors. These gases are adsorbed into the carbon. Later, the carbon can be cleaned and used again.

In gold mining, carbon helps collect gold from liquid mixtures. It holds the gold-cyanide complex, which facilitates easier and cheaper gold recovery.

Carbon removes color, smell, and dirt from sugar, wine, and oil. It must be safe and clean so it doesn’t affect the final product.

Carbon removes harmful gases, such as sulfur, chlorine, and organic pollutants, from industrial gases. This protects machines and reduces pollution.

In chemical factories, activated carbon can adsorb metals (such as palladium) for use in reactions. It can also aid in responses such as dechlorination.

Pictures are for reference only

In industry, carbon must have:

If these are not met, machines may stop or products may be ruined.

Pictures are for reference only

Some important rules include:

In the food and drug industries, it must also meet rules from the FDA, USP, or EFSA. In environmental work, it is essential to comply with EPA regulations.

Over time, large or sticky substances can block the holes. This reduces how well carbon works. It may need to be heated and cleaned, but too much heat can damage it.

Not all carbon works the same. Some jobs need carbon with special pore sizes or chemical coatings.

Some carbon is now changed with chemicals to work better in special tasks, like:

These changes enhance the ability of carbon to interact with specific substances.

This guide is based on:

Activated carbon is not just a filter. It plays an active role in maintaining a clean and safe industry. However, its quality must be protected—clean pores, firm structure, and good reusability matter a great deal.

Following proper standards and using the correct type of carbon helps companies stay efficient and comply with laws. As clean production becomes more critical, activated carbon will be used even more.

Q1: What makes carbon adsorb better?

A: Large surface area, right pore sizes, and chemical surface help it catch more stuff.

Q2: Can it be reused?

A: Yes, it can be cleaned and used again, but it may get weaker over time.

Q3: Why does it stop working?

A: Pores get blocked, it breaks down, or it gets dirty with the wrong chemicals.

Q4: Are all types the same?

A: No. Some are made for food, some for medicine, and some for gas cleaning.

Q5: What is “functionalized” carbon?

A: It’s carbon changed with chemicals to do a special job or react better.

Ningxia Yongruida Carbon Co,.Ltd was founded in

2003.With an area of over 50000 square meters ,our

factory is located in the city of Shizuishan Ningxia .